Principal’s Innovation Award success for Dr Adam Stokes, Dr Philip Hands and Prof Sotirios Tsaftaris

The award scheme, which ran for the first time this year, invited applications from researchers across the University, for “high risk, blue sky projects”, which could be seen as potentially transformational to the economy and pivotal to the development of a whole new sector or technology.

Following a highly competitive application process, Dr Stokes and Dr Hands – both senior lecturers in the Electronics and Electrical Engineering discipline – and Prof Tsaftaris, Chair in Machine Learning and Computer Vision, were selected to receive one of the ten £10,000 prizes on offer, along with a package of research support from the University.

These support packages are designed to accelerate the development of exciting research projects through ambitious and large-scale (£1m+) proposals aimed at novel funding mechanisms such as the Advanced Research Projects Agency (ARPA).

Find out more about the winners and their proposals below.

Dr Adam Stokes: Soft systems for hard problems

The words ‘robot’ and ‘robotics’ conjure images of machines made from metals and plastics, operated using centralised computer control systems, and which are designed to perform dull, dangerous, or dirty tasks in place of humans – often being housed in highly structured, industrial manufacturing environments.

Dr Stokes and his research group – The Soft Systems Group – have, for the last eight years, been transforming and advancing this vision of both the role and the capabilities of robots by using soft materials and fluid-based processes to find new ways of designing, building, operating and integrating smart machines into our everyday lives and environments. ‘Soft robotics’ is a hugely multidisciplinary field which takes inspiration from the academic fields of fluidics and robotics, as well as the forms and processes found in natural biological systems.

Dr Stokes’ current research focuses on creating soft ‘cobots’ to enable interaction between people and machines to perform tasks in critical sectors such as medicine, healthcare, manufacturing, and warehouse fulfilment. The Soft Systems Group have won significant funding from UKRI for the Innovate UK Connect-R project and The ORCA Hub to develop increasingly sophisticated, autonomous robots for operation in extreme environments such as nuclear and offshore settings. A critical factor in the success of deploying robotic solutions is enabling the system to work in unstructured, cluttered, and hazardous environments.

According to Dr Stokes, robotics solutions have only become more urgent and relevant due to the Covid-19 pandemic. “The pandemic has highlighted the need for many more aspects of our lives to be underpinned by systems that are resilient, persistent, decentralised, and sustainable”, he explained.

“The extreme environments in which robots usually operate include industries such as nuclear, mining, space and offshore. The global pandemic has brought public buildings and spaces—hospitals, schools, parks— into the “extreme” category: environments which are dangerous and where physical tasks can be best carried out by robots.”

Dr Stokes and the Soft Systems Group will use the £10k prize money to facilitate workshops with key industrial and academic partners to translate the learning from their award-winning research into the development of new types of “Fluidic Robotics”, and to write research proposals focusing on high-impact, disruptive innovations.

Commenting on the award, Dr Stokes said “This award recognises the robotics research that my group and I are doing here in The School of Engineering and the Edinburgh Centre for Robotics. We are exploring novel ways to build and control machines that are designed for safe-interaction or which provide capability in challenging environments. I look forward to the next phase of our research programme as we explore how to use basic applied research to solve important problems.”

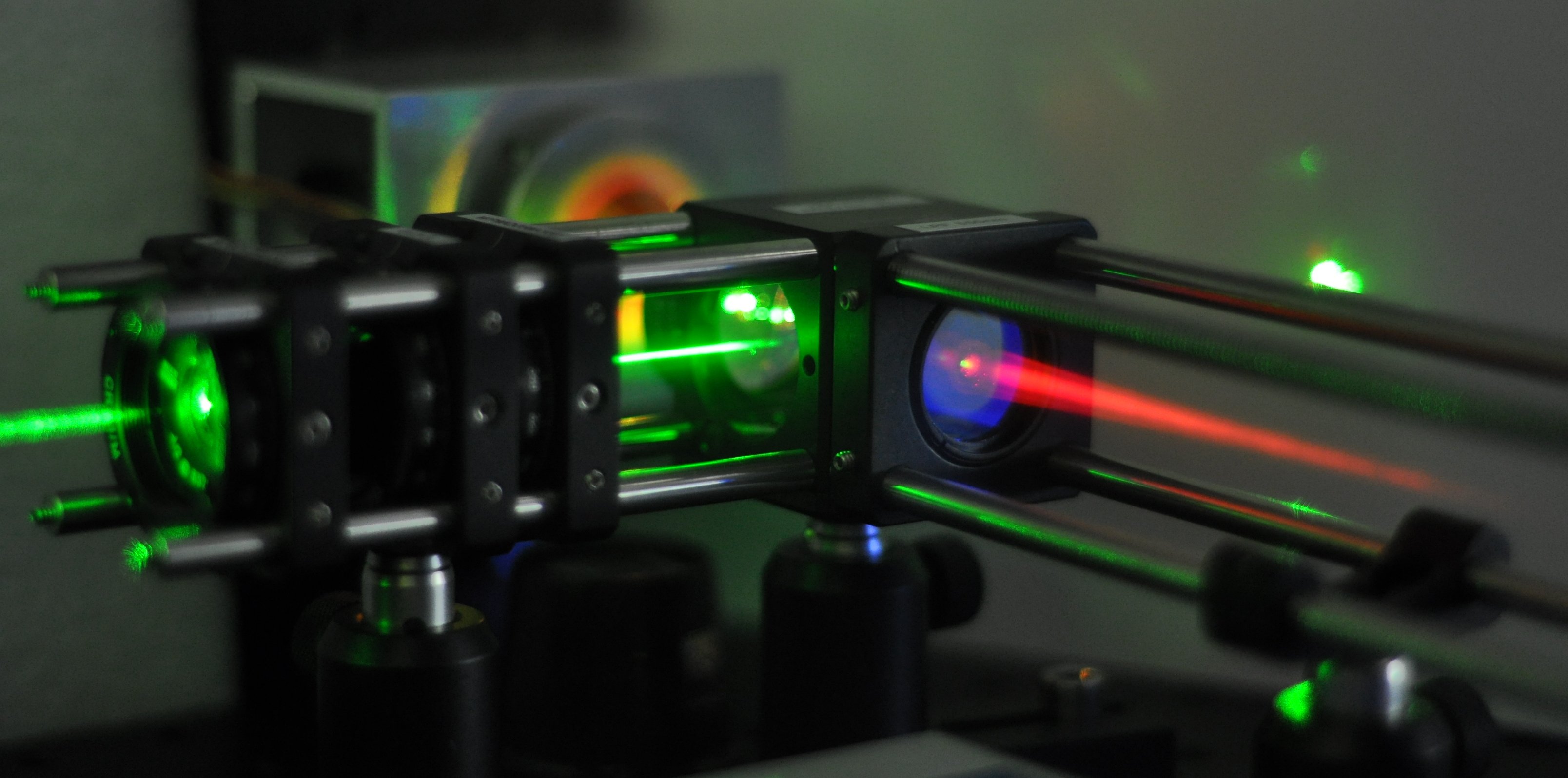

Dr Philip Hands: Liquid crystal microlasers

Dr Philip Hands and his research group have made a recent field-leading breakthrough in liquid crystal microlasers, a cutting-edge technology with the potential to underpin revolutionary new applications in a range of industries, from healthcare to digital communications.

Lasers are devices that generate a very narrow spectrum or single colour of light, usually concentrated into a tight beam- and are often thought of as high precision and high power devices. However, lower power lasers are also integrated into many modern devices such as laser printers, CD and DVD players, barcode scanners, and microscopes for medical imaging.

Lasers can be made in a range of wavelengths, or colours, but some colours are much harder to make than others, meaning there are many gaps in the available spectrum of lasers one can buy. Optical systems must be designed around existing laser availability and have corresponding performance compromises. Lasers that can be wavelength-tuned to any colour are particularly useful and can offer significant advantages, but are generally large, extremely complicated and expensive to buy, and so are rarely integrated into commercial devices.

Using liquid crystals, Dr Hands and his team have developed new lasers that are colour-tuneable anywhere in the visible spectrum, but yet are very small and simple to manufacture. Liquid crystal technology self-assembles at the nano- and micro-scales, meaning that device fabrication is simple and low cost. Their recent breakthrough means that all aspects of the fabrication, including powering the lasers, can now be achieved much more cheaply and easily, in a way compatible with large-scale microfabrication processes such as those used to make microchips and liquid crystal displays.

Image: A liquid crystal laser in the laboratory

Handheld lasers of any colour are now possible, while in the near future, even smaller lasers, less than a hundred microns in size and integrated directly with microelectronics, will also be possible. This breakthrough means that, for the first time, bespoke optimised light fields can be designed for the application, rather than designing the application around the laser.

This new technology will dramatically improve existing laser-based medical imaging and diagnostic devices, for example, through new portable and tuneable-wavelength fluorescence microscopy systems. Liquid crystal lasers are already being tested as sources for multi-wavelength ophthalmic imaging systems, used to identify a wider range of eye conditions with greater speed and accuracy. The ability of the laser technology to be integrated with microelectronics also carries exciting potential for increasingly advanced future uses, from high-bandwidth, high-security optical communications to portable holographic 3D displays and smart wearable electronics devices for remote sensing and wellness monitoring.

Dr Hands and his team will use the award money to pursue an ambitious research proposal, building a multi-disciplinary team involving clinical and biomedical specialists, and electronic, optical and mechanical engineers, and engaging industrial partners in partnership with Edinburgh Innovations.

Reacting to the award, Dr Hands said: “This is an exciting time to be involved in liquid crystal lasers. We believe our recent advances represent the critical breakthrough the field needed to move from a scientific laboratory curiosity to a commercially viable technology. I would particularly like to thank Calum Brown, who was co-applicant for this Award and led the experimental work resulting in this breakthrough. Also from my research group, I would like to thank Daisy Dickinson and Jason Norman, whose excellent research supports this work.”

Prof. Sotirios Tsaftaris: Artificial intelligence for crop performance

The School’s Chair in Machine Learning and Computer Vision, Professor Sotirios Tsaftaris, is working with Professor Peter Doerner, Dr Chris Wood, and Dr Karl Burgess of the School of Biological Sciences on a project to improve the crop yield of plants through artificial intelligence.

Titled ‘Putting the plant in the driving seat: artificial intelligence for crop performance’, the project addresses the global issue of fragile food security, which is expected to worsen thanks to globalised supply chains and the reliance of many countries on imports.

Indoor farming could allow countries to become more self-sufficient by increasing local food production, including in and around urban spaces. However, indoor farming can suffer from productivity problems – as plants did not evolve to thrive and be at their most productive in these environments. Plants have evolved to adapt their growth to constantly changing environmental conditions, and many crops produce on average only 20-40% of their genetically encoded yield potential, due to environmental stress.

Prof. Tsaftaris and his colleagues are working on a plant-computer interface to directly measure a plant’s responses to its environment and subsequently optimise the environment to achieve specific growth outcomes. They are working on a prototype to simultaneously capture root and shoot data to record plant growth activities, with the aim of developing AI that can not only optimise yields but also improve factors such as flavour and nutritional content.

Prof. Tsaftaris commented, “AI is making revolutionary changes in autonomous driving, home assistants and even the assessment of medical images. We have already developed AI techniques that can estimate a plant’s growth (e.g. count leaves) from images. The future is full of promise: we can use AI to not only analyse data but inform how we grow our food.

“This project will help us put key cornerstones in place towards this goal by developing devices that allow AI to collect data and change environmental parameters that help the plant grow. Our end goal is to develop an “AI driver”, one that does not drive a car but controls how a plant is grown.